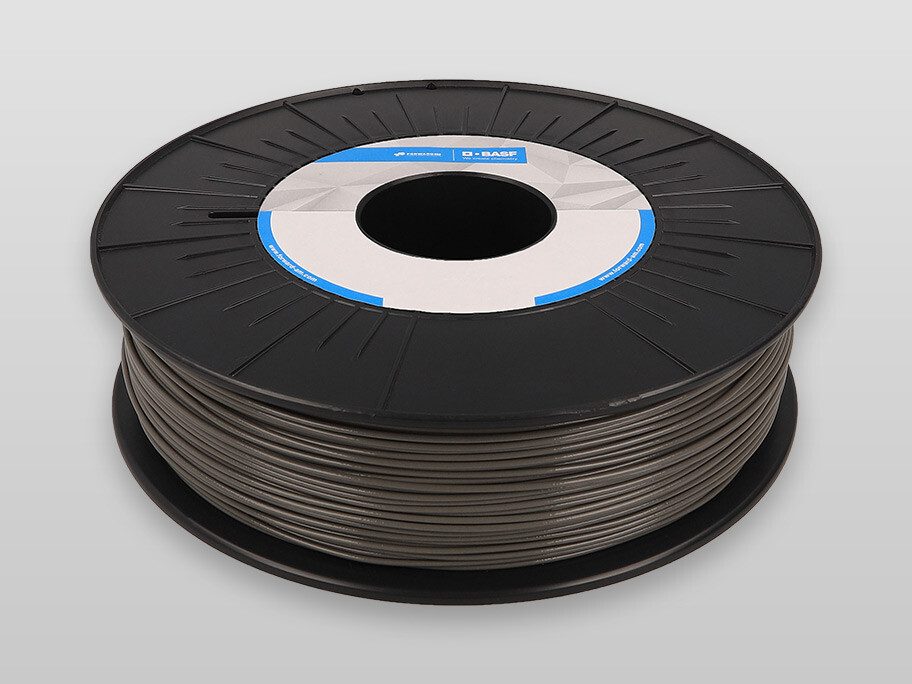

Ultrafuse® 316L

Stainless Steel Composite Metal Filament for 3D Printers

Ultrafuse® 316L is an innovative filament to produce 316L grade stainless steel parts.

Material Details

- Product Leaflet

- Technical Data Sheet: EN, FR, ES, DE, ZH

- User Guidelines

- Debinding Simulation Guidelines

- Process Guidelines

- Safety Data Sheet: EN, other languages

- Printing Profiles

Description

It is designed for ultimate ease of handling on conventional Fused Filament Fabrication 3D printers. BASF Ultrafuse® 316L combines greater freedom of design with a lower total cost of ownership – printing metal parts easier, faster and affordable. Parts printed with Ultrafuse® 316L obtain their final properties, including hardness and strength, through the catalytic debinding and sintering process. The catalytic debinding technology was developed and introduced by BASF and has emerged as the industry standard.

Benefits at a Glance

- Easy and affordable metal 3D printing

- Fast material exchange and easy handling

- For all open source FFF printers

- Produces parts of stainless-steel 316L metal

- Uniform particle distribution enhances mechanical properties

- High flexibility of filament enables successful printing in any FFF printers

- Compatible with both Bowden and direct drive extruders

Example Applications

- Tooling

- Jigs and fixtures

- Functional prototypes

- Small series production

Material Properties

- Excellent corrosive resistance

- Temperature stability

- Austenitic

- Non-magnetic

Print your Parts with Forward AM Materials!

Discover our comprehensive services and solutions here

Use Cases and Whitepaper of Ultrafuse® 316L

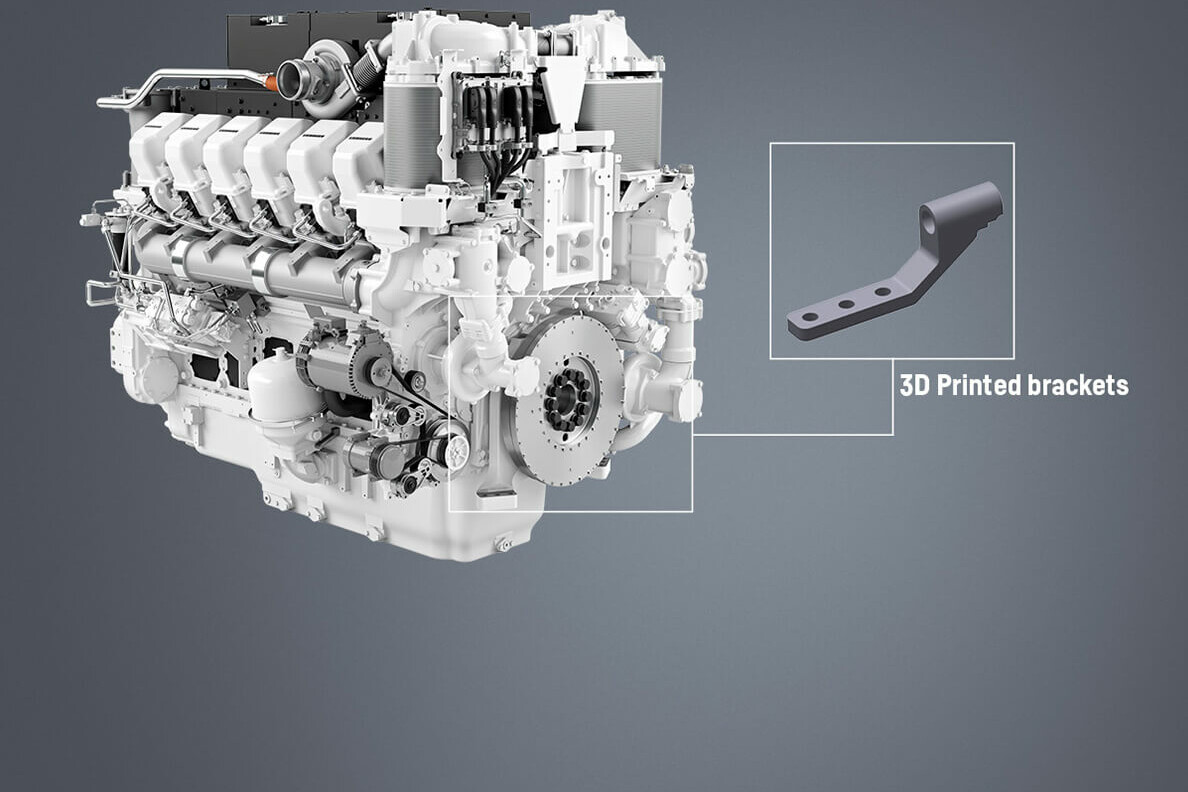

Engine Bracket

When migrating from traditional manufacturing methods to Additive Manufacturing, an experienced and trustworthy AM expert partner is the decisive…

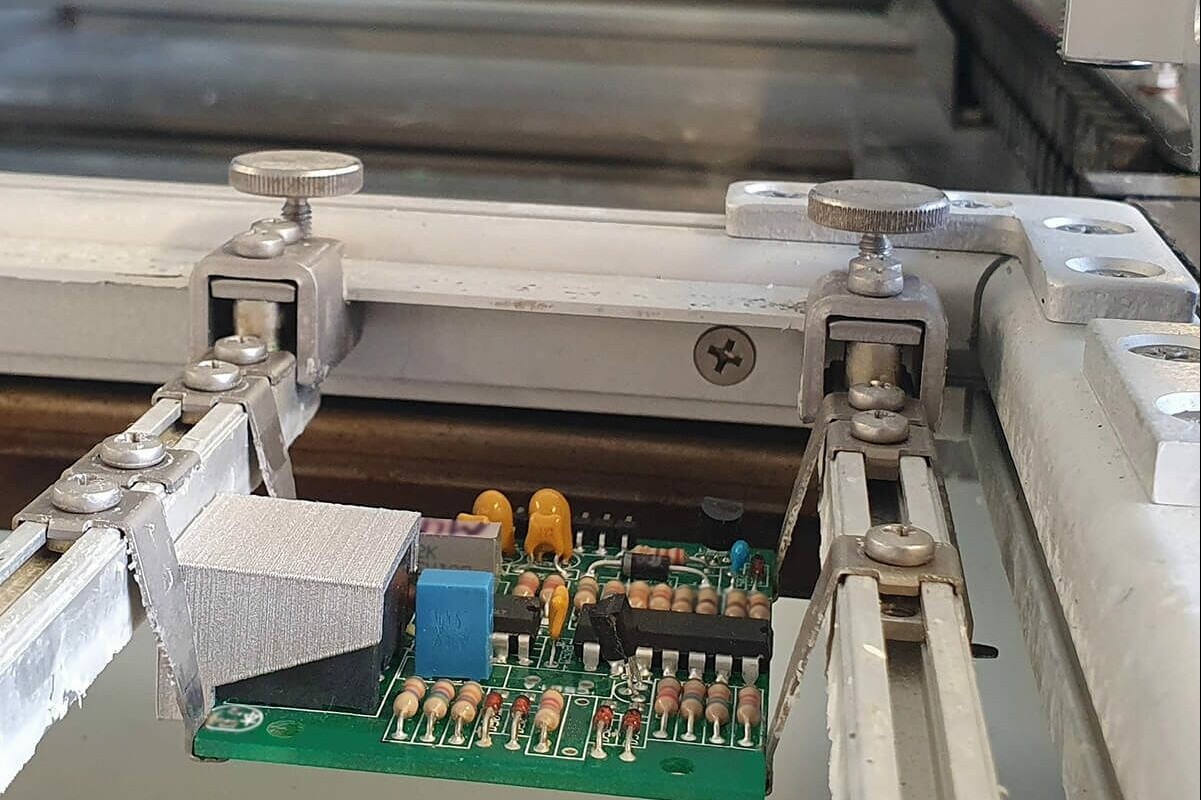

Cover Cap for Electronic Boards

When it comes to the electronics industry, Additive Manufacturing (AM) offers various advantages for manufacturing companies – including faster time…

The #vanlife of the Future – Realized by BASF for HYMER

Global demand for premium Recreational Vehicles (RVs) has been rising continually for several years now and is currently at an all-time high. More…

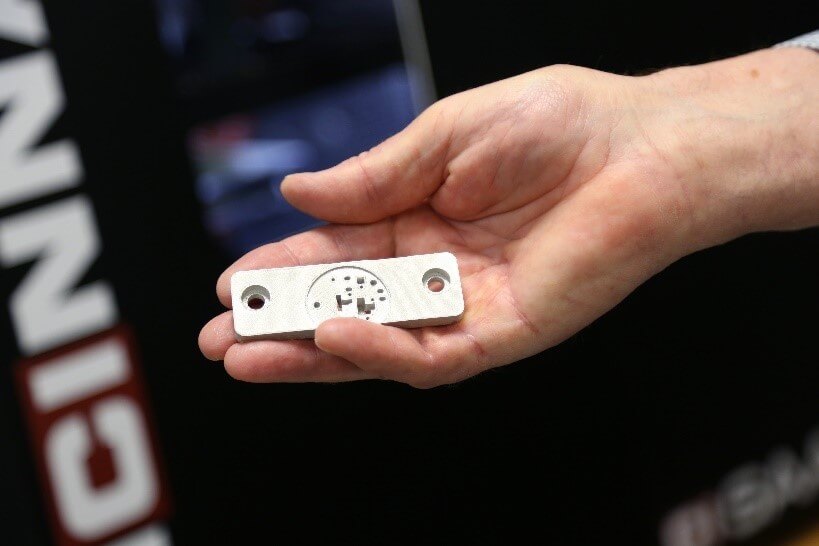

Tooling Fixtures

Electronic communication systems, avionics, space intelligence, cyber security and weather monitoring solutions – American company L3HARRIS…

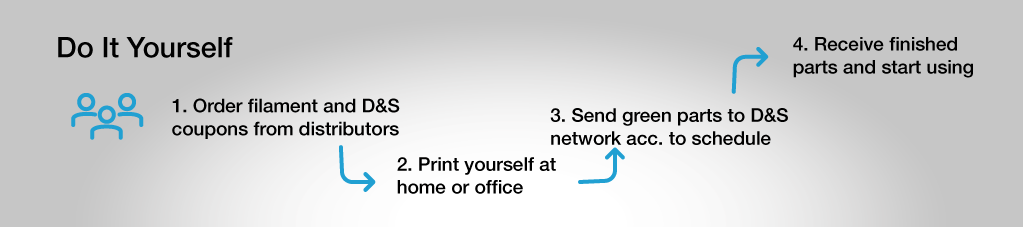

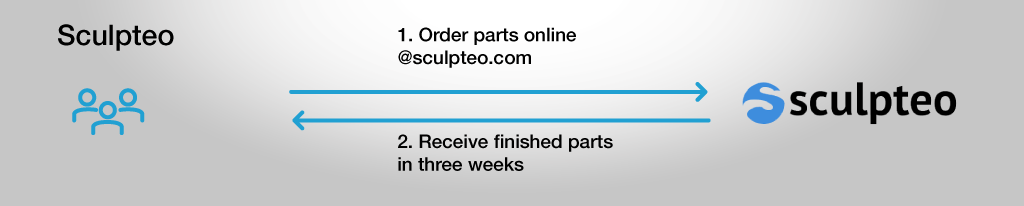

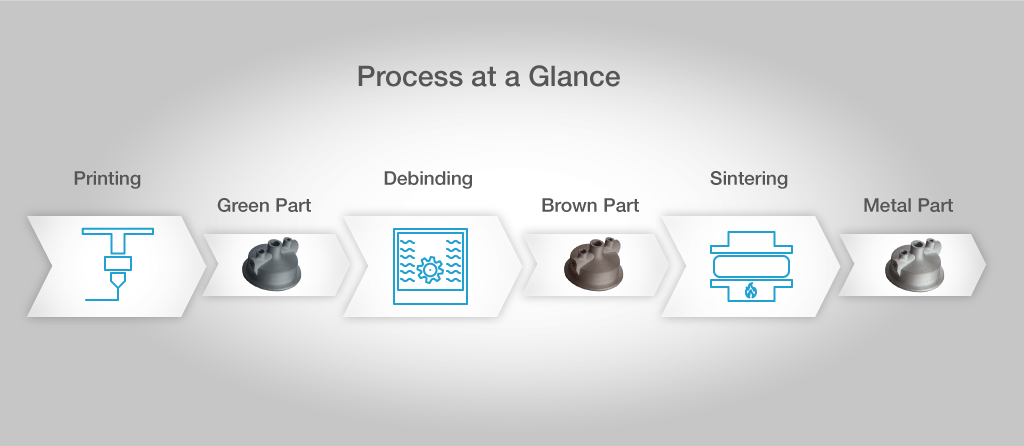

Process at a Glance

In addition to our internal furnace capacities, we have established a D&S network in various regions to be closer to our customers. If needed, we can leverage the service and the long-time experience of DSH Technologies LLC and Elnik Systems GmbH. We are able to utilize and offer their skills and expertise to our customers in North America and Europe. Both entities are affiliates of Elnik Systems LLC in the US, the leading manufacturer of debinding and sintering equipment for industrial production. Our local sales partners can help coordinate and support the shipping of printed green and sintered metal parts between you and our network.

Would you like to try out our material? Please contact our experts.

Do you need your printed green parts debound and sintered? Please contact the local debinding and sintering partner:

DSH Technologies LLC (NA) and Elnik Systems GmbH (Europe)

Easy and cost effective 3D printing of metal parts with Ultrafuse® 316L

We have developed Ultrafuse® 316L to realise high-quality metal parts and high throughput. This state-of-the-art metal filament is suitable for use with any conventional Fused Filament Fabrication (FFF) printer. Following the print, the final properties of the part are then achieved through a debinding and sintering process developed by BASF, which has emerged as the industry standard.

Ultrafuse® 316L is cost-effective, easy to process and meets the MIM industry standard for catalytic debinding and sintering. This innovative industry-grade metal-polymer composite supports a broad range of applications, including tooling, jigs and fixtures, small series production, functional parts, prototypes, and even jewellery.

Ultrafuse® 316L formulates thermoplastic binders with around 90 mass percent of highly-refined metal particles. Our filament has a non-slip surface allowing it to be applied in most Bowden or direct-drive extruders. Thanks to its high flexibility, it can be fed through complex idler pulleys and multiple filament transportation systems in printers – no extra drying required. As a filament, the metal-polymer composite comes with none of the occupational and safety hazards associated with the handling of fine metallic powders, making 3D printing of stainless-steel parts affordable, straightforward, and safe.

Which 3D printers should I use with Ultrafuse® 316L?

Designed for secure and easy handling on conventional, open-material Fused Filament Fabrication (FFF) printers, Ultrafuse® 316L comes with a wide processing window. To help you succeed in 3D printing metal parts we provide printer processing guidelines including Ultrafuse® 316L parameter sets. In addition, consultancy and on-site support are available to help ensure the material performs on your printer.

Do You Want to Order Ultrafuse® 316L?

Next Steps

Printing Profiles

Select your printer below to access your printer profile. Click here to learn more about how to work with printer profiles.

Get in touch

Do you have questions about our materials, technologies or services? Get in touch now!

More Metal Filaments

Ultrafuse® 17-4 PH

The Filament Enabling Stainless Steel Parts for Applications that Require High Hardness and Mechanical Strength

Benefits at a Glance

- High mechanical strength and hardness

- Easy and affordable way of metal 3D printing

- Good corrosion resistance

- Fully hardened enables highest strength

- Wide range of post-processing options for green parts

Ultrafuse® Support Layer

Ultrafuse® Support Layer creates a barrier during sintering and facilitates the separation of support from the metal part

Benefits at a Glance

- Printable on any metal FFF printer

- Allows for a wider range of designs and complex geometries to be printed

- Excellent surface quality of supported areas of the part

- Minimize the distortion of the printed part during debinding and sintering